Out Of This World Info About Can You Glue Two Wires Together

How To Twist Electrical Wire Together? (2) YouTube

Can You Glue Two Wires Together? Let's Untangle This!

1. The Short Answer — And Why It Matters

So, you're wondering if you can just slap some glue on two wires and call it a day, huh? Well, the short answer is... it's complicated. Technically, yes, you can glue two wires together. But should you? That's where things get interesting. Think of it like this: you can use a spoon to cut steak, but there are much better tools for the job. Using glue as your primary method for connecting wires is generally not recommended — unless you enjoy electrical fires and unreliable connections.

Why the hesitation? Well, standard glues aren't designed to conduct electricity. In fact, most are insulators. This means they'll block the flow of electrons, which is kinda the whole point of wires. Imagine trying to get water through a pipe filled with... well, glue! Not gonna happen, right?

Besides the conductivity issue, glue isn't a particularly strong or durable connection method for wires. Wires are often subject to movement, vibration, and temperature changes. Ordinary glue can crack, peel, or simply lose its grip over time, leading to a broken connection and potentially dangerous situations. Plus, depending on the type of glue, it could corrode the wires themselves! Now, who wants rusty wires?

So, while it's possible to glue wires, it's generally a bad idea. There are much safer and more reliable ways to connect wires that won't leave you with a headache (or a house fire). But before we explore better options, let's dive deeper into why this seemingly simple task is more complex than you might think.

How Do You Stick Two Wires Together? Glue Things

Why Glue Isn't the Ideal Wire Connector

2. Digging Deeper Into the Problems

Okay, so we've established that glue isn't exactly the king of electrical connections. But let's really hammer home why it's a less-than-stellar choice. Imagine building a house with cardboard — it might look okay initially, but it's definitely not built to last. That's kind of what you're doing when you rely solely on glue to join wires.

One of the biggest issues is electrical resistance. Even if a thin layer of glue allows some electricity to pass through, it's going to create resistance. This resistance generates heat, and heat is the enemy of electrical components. Over time, this heat can damage the wires, the glue, and even surrounding materials. Think of it like a kink in a garden hose — the water still flows, but not as efficiently, and the pressure builds up.

Another concern is environmental factors. Humidity, temperature fluctuations, and even just the passage of time can degrade glue. This degradation weakens the connection, making it more prone to failure. And when an electrical connection fails, you could be looking at anything from a flickering light to a complete power outage. Not fun!

Finally, consider the long-term reliability. Soldering, crimping, or using proper connectors creates a mechanical bond that's far more robust and resistant to environmental changes. Glue, on the other hand, is essentially a temporary fix that's just waiting to fail. So, while it might seem like a quick and easy solution in the moment, it's likely to cause more problems down the road. Save yourself the future frustration!

Can You Use Hot Glue To Connect Wires? Things

Better Ways to Connect Wires

3. Safer, Stronger, and More Reliable Options

Alright, enough about the downsides of glue. Let's talk about the good stuff — the reliable, tried-and-true methods for joining wires that electricians actually use (and recommend!). These methods ensure a safe, secure, and long-lasting connection.

First up, we have soldering. Soldering involves melting a metal alloy (solder) onto the wires, creating a strong electrical and mechanical bond. It's like welding for tiny electrical components! Soldering requires some skill and the right tools (soldering iron, solder, flux), but it creates a very durable connection that's resistant to corrosion and vibration. Think of it as the gold standard for wire connections.

Next, there's crimping. Crimping uses specialized connectors and a crimping tool to create a tight, gas-tight seal between the wires and the connector. This method is fast, easy, and doesn't require any heat. Crimp connectors come in various shapes and sizes for different wire gauges and applications. It's like using a staple gun for wires, but with a much more secure and electrically sound result!

Finally, we have wire connectors (like wire nuts or push-in connectors). These connectors are designed to twist or clamp the wires together, providing a secure electrical connection. They're incredibly easy to use and are ideal for connecting wires in junction boxes or electrical panels. They are often color-coded to help guide you. It's the most straightforward way for beginners to start connecting wires.

These are some of the best methods to connecting wires and remember that electrical safety should be a priority. If you're unsure about any electrical work, it's always best to consult a qualified electrician. Trust me; your safety (and your home's electrical system) is worth it!

How To Tie Two Wires Together At Murray Blog

Special Glues

4. When Glue Can Be Used (With Caution)

Okay, so we've been pretty down on using glue for wire connections. But, as with most things, there are exceptions! There exist specialized adhesives designed for electrical applications. These conductive adhesives and epoxy resins are formulated with conductive particles (like silver or copper) that allow electricity to flow through the bond. However, it's crucial to understand their limitations and use them only in appropriate situations.

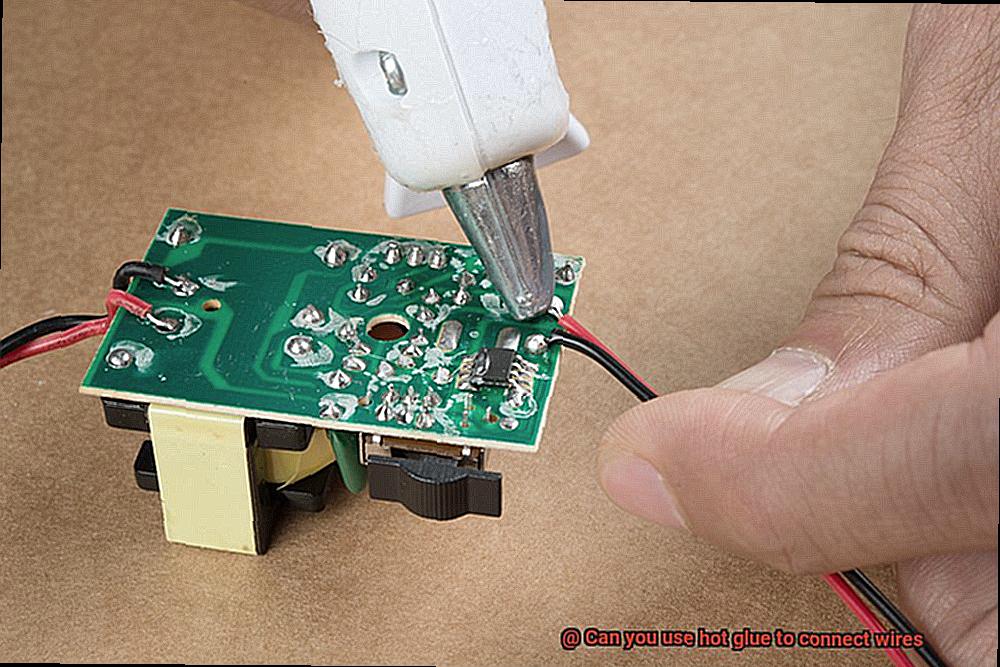

Conductive adhesives are often used in electronics manufacturing for bonding components to circuit boards or for repairing broken traces. They're particularly useful when soldering is not an option, such as when working with heat-sensitive components. Think of them as a niche tool for specific jobs, not a general-purpose wire connector.

Epoxy resins are sometimes used for potting or encapsulating electrical components, providing insulation and protection from the environment. These resins can also be formulated with conductive additives to create a conductive path. But again, it's essential to choose the right type of epoxy and follow the manufacturer's instructions carefully.

The critical thing to remember is that even these specialized adhesives are not a replacement for proper wiring techniques like soldering or crimping in most situations. They typically have lower conductivity and mechanical strength compared to traditional methods. So, use them sparingly and only when specifically recommended for the application. Think of them as the exception that proves the rule!

Safety First

5. Protect Yourself & Your Electrical System

Before you even think about touching a wire — glue or otherwise — safety should be your absolute top priority. Electricity is powerful and potentially dangerous, so it's crucial to take the necessary precautions to protect yourself and your electrical system. Imagine it as a construction site; hard hats and safety glasses are not optional; they are essential!

The first and most important rule: Always disconnect the power before working on any electrical circuit. Flip the circuit breaker or remove the fuse that controls the circuit you'll be working on. Double-check that the power is off using a non-contact voltage tester. Never assume that the power is off just because you flipped a switch. Remember, better safe than sorry!

Next, use the right tools for the job. Insulated pliers, screwdrivers, and wire strippers are essential for safe and effective electrical work. Never use damaged or makeshift tools. And wear appropriate personal protective equipment, such as safety glasses and insulated gloves. Think of it as preparing for battle — you need the right armor to protect yourself.

Finally, if you're unsure about any aspect of electrical work, don't hesitate to call a qualified electrician. Electrical work is not something to take lightly. A mistake can lead to serious injury or even death. So, if you're not confident in your abilities, leave it to the professionals. After all, it's better to pay a little extra for peace of mind than to risk your safety.

FAQ

6. Your Burning Questions Answered

Let's tackle some of the most common questions surrounding wire connections and electrical work.

Q: Can I use electrical tape instead of a proper connector?A: Electrical tape is designed to insulate wires, not to provide a mechanical connection. While it can be used to cover a properly joined connection (like a soldered joint), it should never be used as the sole method of joining wires.

Q: What's the best way to strip insulation from a wire?A: Use a wire stripper! It's designed to remove the insulation without damaging the wire. Be sure to use the correct gauge setting to avoid nicking the wire, which can weaken it.

Q: How do I know what size wire to use for a particular application?A: The correct wire size depends on the amperage of the circuit. Consult an electrical code book or a qualified electrician to determine the appropriate wire gauge for your specific needs.